Knowledge-driven improvement: The Constructing Blocks of Success

Knowledge is the brand new gold. This much-quoted assertion is especially true relating to car improvement. Knowledge analyses and data-driven improvement primarily based on them have gotten more and more essential on this discipline. And that’s no surprise, as they permit engineers to acquire quicker insights into the present efficiency of recent car features—and to attract conclusions from early phases, see what works, and establish the place there are nonetheless points. “With the assistance of data-driven improvement, we are actually able to optimize new features rather more rapidly and expedite their market maturity,” studies Leon David Lange, Mission Lead ADAS Knowledge Evaluation at Porsche Engineering. “With out this acceleration, notably advanced car options couldn’t be realized in any respect in an inexpensive time.”

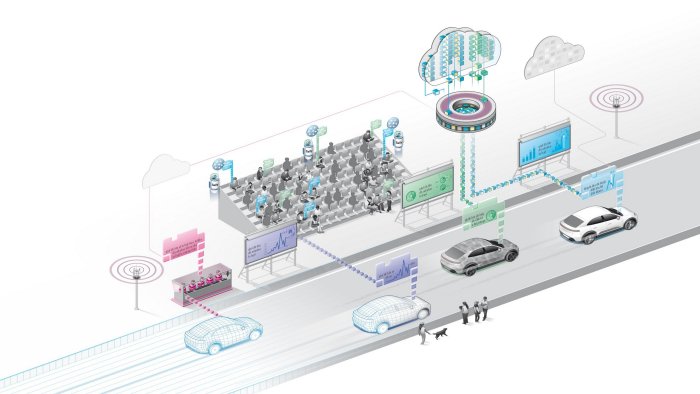

Nevertheless, the quick suggestions loops from the event or testing section require a software chain that’s as seamless as doable. “The advantages of data-driven improvement might be totally utilized in case you have the mandatory instruments alongside all the improvement chain,” explains engineer Dr. Hagen Stübing, Senior Supervisor Software program Engineer at Porsche Engineering. “That is why a number of specialist disciplines at Porsche Engineering have developed an built-in modular set of instruments for various improvement phases. These instruments optimize the event course of each when utilized in isolation and as an entire vary of instruments – from recording and evaluating the info within the car to its transport to the backend, storage, and evaluation within the cloud, by means of to the switch of recent software program variations again to the car.”

“With the assistance of data-driven improvement, we are actually able to optimize new features extra rapidly and expedite their market maturity.”

Leon David Lange, Mission Lead ADAS Knowledge Evaluation at Porsche Engineering

The software chain has a modular construction and might due to this fact be flexibly tailored to the person necessities of each trade buyer. “Some prospects solely want the instruments throughout improvement, whereas others need to use them end-to-end – that’s, all through all the life cycle of a brand new car,” says Dr. Heiko Helble, Mission Lead for Knowledge Gatherers at Porsche Engineering. “Modularization signifies that we will adapt to any request. “Porsche Engineering has developed a software chain in-house that can be utilized from the preliminary improvement steps to endurance testing and collection manufacturing. This will increase the pace with which modifications out there might be responded to—with custom-fit instruments on the proper time.

Portfolio of six instruments

The Porsche Engineering portfolio at the moment consists of six instruments for data-driven improvement: The Automated Measured Knowledge Analysis Software (AMDA V2) has been developed to judge measurements routinely, and immediately within the car. It’s used within the early improvement phases. When the car is nearer to collection manufacturing, the Porsche Engineering Knowledge Gatherer (PEDG) that’s built-in within the car will then be used to gather knowledge. The ComBox app, which runs on a typical Android smartphone, gives help for knowledge provision and validation of check drives (see the detailed Report beginning on web page 30). The LLM service platform SALLY focuses on use in car improvement. SALLY is a digital assistant that helps builders. The PE IoT edge platform (PEvIoT) manages gadgets reminiscent of measurement know-how through 5G from the cloud. It’s built-in right into a vehicle-based PC. The PEvIoT platform transfers all recorded knowledge to an information lake within the cloud— the Porsche Engineering Knowledge Hub (PEDH). “Our instruments incorporate the expertise gained from a few years of auto improvement at Porsche Engineering,” says Daniel Schumacher, Specialist for Cloud Structure at Porsche Engineering. “We are able to advance and adapt the instruments and, as a improvement service supplier, put them into use, as a result of they have been developed fully in-house.” Porsche Engineering makes use of the software chain in improvement initiatives, nonetheless additionally affords it to trade prospects as “software program as a product” through licensing. All instruments might be booked on a modular foundation, however the advantages provided by the general bundle are notably excessive.

“The advantages of data-driven improvement might be totally utilized of you may have the mandatory instruments alongside all the improvement chain.”

Dr. Hagen Stübing, Senior Supervisor Software program Engineering at Porsche Engineering

Automated Measurement Knowledge Analysis – AMDA V2

AMDA V2 (Automated Measured Knowledge Analysis Software, model 2) is software program for evaluating measurement knowledge routinely and immediately on the level of origin. It has entry to the info buses of the check car, which signifies that it may learn the complete knowledge site visitors dwell and instantly analyze related alerts whereas the car is shifting. On this method, AMDA V2 is ready to detect sure driving situations, reminiscent of a car in entrance merging. On the similar time, AMDA V2 data the response of the car features—on this instance, the response of the adaptive cruise management longitudinal controller to the merging street consumer. Utilizing key efficiency indicators (KPIs) primarily based on car knowledge, the software then objectively assesses whether or not the system has dealt with the state of affairs effectively or not sufficiently. Evaluation immediately within the check car utilizing AMDA V2 signifies that no massive quantities of knowledge should be transferred to the cloud for analysis. This not solely reduces improvement prices, but additionally contributes to extra environment friendly check procedures and will increase the target assessability of a perform.

Knowledge Gatherers in Collection Manufacturing Automobiles – PEDG

The Porsche Engineering Knowledge Gatherer (PEDG) is a knowledge collector designed for collection use. In distinction to AMDA V2, the software doesn’t run on separate {hardware} (a PC within the car or pocket book), however might be embedded in an current collection management unit. That is why the PEDG is barely utilized in later improvement phases and after the beginning of collection manufacturing. The PEDG might be set remotely utilizing cellular know-how (over-the-air) to routinely detect sure processes—for instance, switching on a car system or emergency dealing with of a state of affairs. On this case, the software routinely data all related alerts and routinely returns them to a again finish, the place additional analyses can then be carried out. The nice benefit of the PEDG is that it’s doable to file knowledge in series-produced fleets with out the necessity for bodily entry to the autos, for instance by visiting a workshop.

LLM Service Platform for Growth – SALLY

SALLY is a platform within the cloud that software program builders can entry through their computer systems and that aids them of their work by performing as a digital assistant. Customers can, for instance, entry details about the present standing of tickets for particular occasions and obtain help when engaged on new software program features through a immediate in pure language. In distinction to well-known massive language mannequin (LLM) platforms reminiscent of ChatGPT or Deep Search, SALLY has entry to area data from the event of superior driver help programs (ADAS); additional area data is dockable. This enables SALLY for use in areas reminiscent of creating ACC features—on the one hand, to effectively retrieve data from the necessities and, alternatively, to supply direct help throughout software program improvement. For instance, the software can create code snippets, right code, and create documentation from current code.

This enables new software program features to be created, analyzed and examined extra rapidly. Specifically, the time required for troubleshooting and subsequent set up on check autos is considerably lowered. This makes SALLY a improvement accelerator within the space of recent ADAS features. The SALLY platform has an software programming interface (API) by means of which additional AI purposes might be arrange and current companies built-in.

Digital Assistant for Check Drives – COMBOX APP

The ComBox app is a software program that runs on a smartphone and serves as a digital assistant for the check driver. Throughout check drives, it accesses the car knowledge from the info logger routinely or after a handbook set off; the info is then transferred to the cloud through the cellular community—and in some instances is pre-processed utilizing AI. Presently, the ComBox app affords six completely different modes: Primary service, site visitors signal recognition, scene recognition, acoustic complaints, infotainment recording in addition to automated shift and check studies.

“Our instruments incorporate the expertise gained from a few years of auto improvement at Porsche Engineering.”

Daniel Schumacher, Specialist for Cloud Structure at Porsche Engineering

Knowledge Lake within the Cloud – PEDH

The Porsche Engineering Knowledge Hub (PEDH) is one other cloud platform from Porsche Engineering that may log all recorded knowledge from the check autos in a knowledge lake and retailer it in a folder construction—akin to the file explorer on a PC, solely scalable to a complete fleet of improvement autos.

Builders within the Porsche community can entry it, whereas indexing the metadata for the uploaded information permits for environment friendly filtering and looking out. This makes it doable to instantly see info reminiscent of which car uploaded the info, which instruments have been used for recording it, and which software program model was put in on the management items.

Linked to the Cloud – PEVIOT

The PE IoT edge platform (PEvIoT) connects gadgets to the cloud, such because the measurement know-how within the car or the PCs on HiL (hardware-in-the-loop) check benches. It runs on a vehicle-based PC that’s related to the Web (through 5G, for instance). PEvIoT can be utilized not solely to transmit measurements, but additionally to put in or replace different instruments reminiscent of AMDA V2 within the car—simply and totally routinely. Docker containers are used to dispatch the instruments; these bundle software program along with all dependencies reminiscent of working system libraries, software program frameworks or databases. This ensures easy operation in a variety of laptop environments. PEvIoT permits the usage of completely different instruments within the car and considerably reduces the time required for commissioning them. On the similar time, updates might be distributed flexibly and whole car fleets might be managed conveniently from a distant location.

Information

Textual content first printed in Porsche Engineering Journal, subject 1/2025.

Textual content: Christian Buck

Illustrations: Andrew Timmins

Copyright: All photographs, movies and audio information printed on this article are topic to copyright. Copy in complete or partly shouldn’t be permitted with out the written consent of Dr. Ing. h.c. F. Porsche AG. Please contact magazin@porsche-engineering.de for additional info.

Source link