ComBox app: Evaluating measurement knowledge on the contact button

Drivers of improvement autos have already got their fingers full figuring out, documenting and reporting technical abnormalities of latest automobile features to the respective improvement departments throughout their take a look at drives. “We welcome any simplification of our work, particularly with regard to ADAS and drive points, the validation of which is especially time-consuming,” experiences Jan Wörner, Undertaking Supervisor in Information Pushed Testing & Car Features at Porsche Engineering. “That’s precisely why we developed the ComBox app: It’s the engineer’s companion and serves as a form of digital assistant throughout the testing. It additionally performs many calculations instantly within the automobile and identifies necessary eventualities within the measurement knowledge with out the motive force having to intervene. This edge computing means we’ve got to ship considerably much less knowledge to the cloud for analysis.”

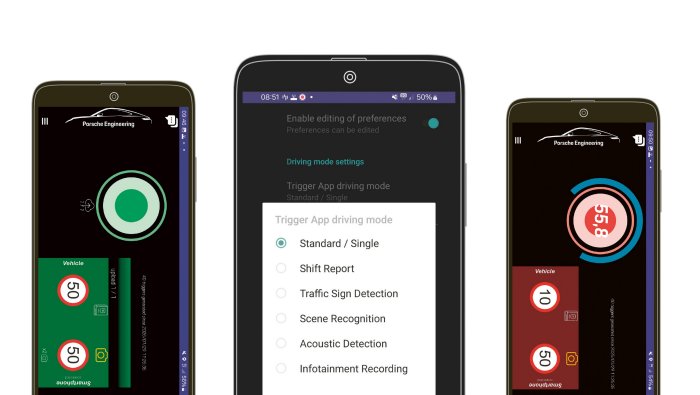

Six modes to select from

A commercially out there high-end smartphone serves because the platform for the ComBox app. Many of the computing assets of this smartphone can be found to the help software program developed by Porsche Engineering. After launching the app, the person can choose from six completely different modes: “Normal / Single” can be utilized to set off measurement of auto management unit knowledge at any time with a purpose to file this measurement knowledge and add it to the cloud. “Scene Recognition” mode can file basic site visitors eventualities which are related for ADAS features, for instance.

“Acoustic Detection” mode makes use of AI assist to search out distracting noises, whereas “Infotainment Recording” affords assist with correcting show issues. “These 4 modes have one factor in widespread: After a guide or computerized set off, they file patterns or errors and ship the corresponding knowledge to the cloud,” says Wörner. “Shift report” mode is used after the take a look at drives and reduces the work concerned in creating the log. “All modes cut back the guide workload, which will increase effectivity and cuts human errors within the testing and fault elimination course of,” explains Wörner.

Entry to the automobile buses

The prerequisite for that is that every one modes have entry to the related automobile buses and knowledge. The ComBox app obtains this knowledge from a knowledge logger within the take a look at automobile, similar to Porsche Engineering’s Automotive Information Field. “The info logger has full entry to all bus programs similar to CAN, LIN, FlexRay, and Automotive Ethernet, which it makes use of to supply details about the present standing of all automobile programs,” explains Wörner. “It forwards this knowledge to the smartphone with the ComBox app – both by way of cable utilizing an Ethernet-to-USB adapter or by way of WiFi, if there’s a wi-fi entry level within the automobile that’s linked to the info logger.”

With the ComBox app’s Normal / Single service, the motive force can set off a measurement manually if any abnormality happens. “Which means that all measurement knowledge from the automobile is recorded inside an outlined timeframe across the set off time and loaded into the cloud. The timeframe might be, for instance, from three minutes earlier than the set off time to a few minutes after it,” says Wörner. “The motive force may enter a voice rationalization into the smartphone, which is then robotically transformed into textual content and despatched to the cloud along with the measured knowledge by way of a 5G community. With this technique, detailed extra data will be recorded instantly and thereby be made out there at once for the downstream error evaluation. The opposite modes additionally provide this feature.“

„Acoustic Detection” mode robotically identifies sure undesirable noises within the automobile and, below sure framework circumstances, offers assist with figuring out the trigger. “The ComBox app makes use of the smartphone’s high-quality microphone to detect the background noise. This makes dependable detection potential that’s as cost-effective as it’s space-saving—and with none extra tools. Nonetheless, those that want to can nonetheless join particular microphone know-how,” Wörner explains. “Synthetic intelligence is used to investigate the audio recording instantly within the automobile: We use a neural community that we’ve got skilled with noise interference patterns.”

If the ComBox app detects an undesirable sample, it robotically generates a message to this impact and hundreds it into the cloud along with the related audio 昀le. Different measurements similar to the present pace of the automobile, the gear engaged, and the engine pace are additionally transmitted. This intensive automation considerably reduces the workload required. For instance, ”Acoustic Detection“ mode can robotically detect the signature howling noise of turbochargers, in addition to sure intrusive wind noises. The checklist of robotically identifiable noise varieties will probably be expanded to incorporate additional noise classes sooner or later. As well as, the neural community has additionally discovered how regular driving sounds as a reference. Utilizing the ComBox app can considerably cut back the trouble concerned in detecting and analyzing acoustic points.

“Prior to now, there was usually no appropriate measuring tools within the automobile when such anomalies occurred,” experiences Wörner. “We due to this fact first needed to equip a automobile with the measuring know-how after which intentionally recreate the fault. This was very time-consuming and related to excessive prices.” Abnormalities within the infotainment system can be logged utilizing the ComBox app. That is the place “Infotainment Recording“ mode is available in. This mode information the content material of the screens (driver, central, and passenger show) whereas the automobile is transferring. If the take a look at driver notices an issue, a easy press of a button within the app will suffice to robotically add a brief video to the cloud. The video additionally incorporates the display content material from a number of seconds earlier than the perform was triggered,” says Wörner. “Abnormalities similar to misaligned textual content, an incorrectly positioned icon within the navigation system or the improper ingredient being overlaid often solely seem for a number of seconds, which is why we have been usually unable to file them in time up to now. ‘Infotainment Recording’ mode provides us much more room to determine and flag such points.”

Automated scene recognition

„Scene Recognition“ mode continues to be below improvement. It goals to robotically detect typical site visitors eventualities which are related for testing a brand new ADAS perform, similar to being lower off by a automobile in entrance—an incident that the ACC perform, for instance, might have to counter by braking. Such eventualities are described by the indicators that happen within the automobile and the order they happen in. These indicators embrace the present pace, the brake stress, and the space to the highway person in entrance. Edge computing instantly throughout the app permits even complicated eventualities and take a look at cycles to be detected intelligently and robotically, with out the motive force having to intervene.

“We are able to ship a selected state of affairs sample – containing the sequence of occasions and the mixture of indicators – from the cloud to all autos geared up with the ComBox app,” says Wörner. “As quickly because the sample you’re in search of seems someplace, the ComBox app sends the present measurement knowledge to the cloud. This enables builders to see whether or not the brand new automobile perform has responded as desired.” The large benefit right here is that, sooner or later, all autos in a take a look at fleet which are working the ComBox app can be utilized to seek for the related patterns – and never simply these autos which are, for instance, particularly on the highway for ADAS testing functions. “This protects loads of time,” says Wörner, “as a result of we not have to hold out sure devoted take a look at drives individually. They’re executed by different autos alongside the best way, so to talk.”

“Shift report” mode drastically facilitates the documentation of take a look at drivers and measurement outcomes. For high quality assurance functions, new autos bear intensive endurance exams that embrace many repetitions – for instance, opening the bags compartment and sliding the sunroof a number of instances or repeatedly charging the battery. This mode makes use of automobile measurement indicators to partially fill out the experiences robotically—with knowledge such because the variety of repetitions carried out. The experiences want solely to be checked after the journey and corrected if essential. What’s extra, the motive force can file all errors that happen whereas driving instantly within the ComBox app and add images if essential.

“After every journey, the motive force fills out a report and signifies how usually they’ve carried out which motion,” explains Wörner. “Finishing these experiences manually means a substantial amount of work and, as with all guide exercise, errors can creep in. That is the place the app successfully cures the issue and we will improve the standard of the experiences.” The six modes of the ComBox app have already proved themselves in follow and are continually being enhanced. “The ComBox app thus serves as a dependable assistant for testing and, on the similar time, features as a central knowledge interface,” Wörner sums up. “One other benefit is its potential for use seamlessly and comprehensively for kind of all automobile derivatives. Sooner or later, Porsche Engineering plans to supply this instrument, together with the backend within the cloud, to its industrial clients as a self-contained product. The app’s completely different modes will be added on individually relying on buyer necessities.

Data

Textual content first revealed in Porsche Engineering Journal, difficulty 1/2025.

Textual content: Christian Buck

Copyright: All pictures, movies and audio information revealed on this article are topic to copyright. Copy in complete or partially shouldn’t be permitted with out the written consent of Dr. Ing. h.c. F. Porsche AG. Please contact magazin@porsche-engineering.de for additional data.

Source link